Thiol pre-cursors have been shown to be exceptionally vulnerable to irreversible oxidation, depleting the pool of potential aromas. Unfortunately, many aspects of juice extraction result in high levels of dissolved oxygen (DO) pickup, particularly crushing and de-stemming. It is not unusual to see DO levels in excess of 7mg/l, which is near saturation point.

Addition of SO2 does little to improve this, as its modes of action are not fast enough for this level of DO. Ascorbic acid is very effective against oxidation but brings its own problems of managing sufficient free SO2 levels, to avoid spontaneous browning.

Oenofrance® offers a more manageable option by way of Phylia® AR. An inactivated yeast rich in amino acids and small peptides which has been shown to have a high antioxidant capacity. For maximum effect, this should be added as early as possible during the vinification process, even at the machine harvester.

As most thiol precursors are found in the skins of the berries, their concentration can easily be increased by skin contact. Whilst very effective, this can tie up the press for a significant period of time, thus reducing the processing capacity of the winery. With this in mind, Oenofrance® has developed Lysis® Intense, a highly active pectolytic enzyme for skin contact.

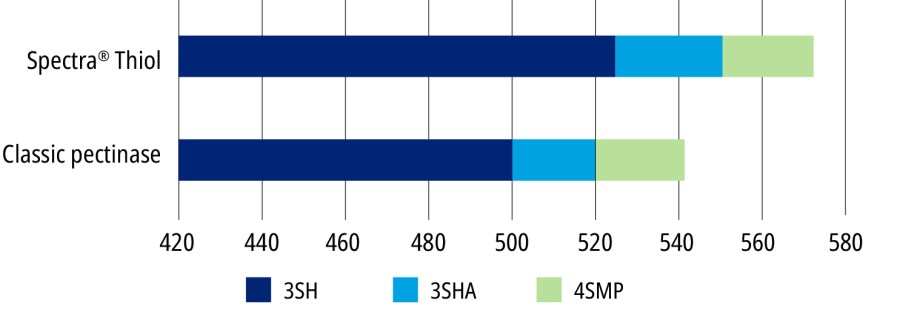

An alternative approach is to use stabulation, holding the unclarified juice at below 4˚C for around seven days. For this approach Spectra® Thiol has been specifically developed to optimize extraction and the release of thiol precursors. This not only reduces the time to four days, but also enhances volatile thiol levels in wines compared to other enzymes (Figure 1).

Figure 1: Volatile thiols concentrations in finished wines

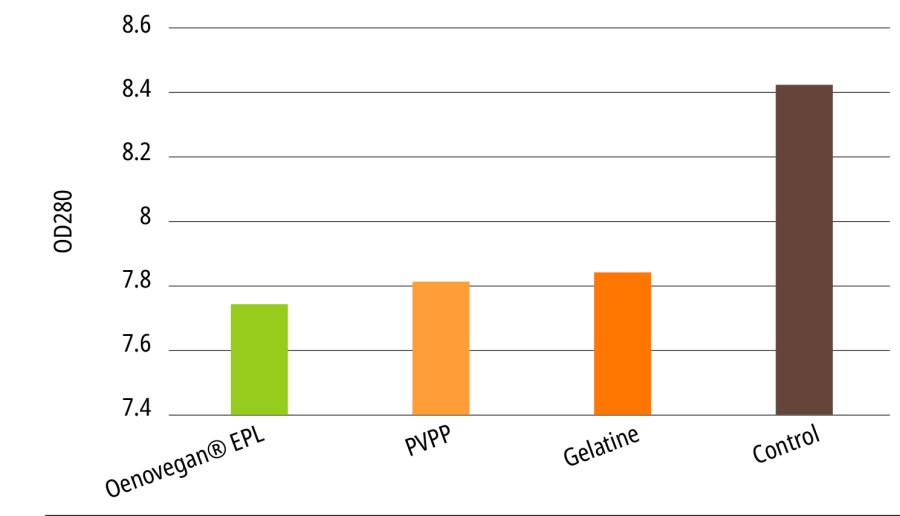

A secondary effect of extended skin contact is that it will also give rise to higher phenolic content, potentially increasing the astringency. The traditional approach to this has been fining with animal derived protein (isinglass, gelatine etc). These are very effective but concerns over allergen content has significantly limited their use. To overcome this problem, Oenofrance® has developed Oenovegan® EPL, a synergistic combination of plant protein and yeast protein extracts to optimise fining. It provides good clarification by flotation or static fining. It also reduces oxidised (bitter) and easily oxidisable polyphenols, while preserving the varietal characteristics of the must.

Perhaps the most important consideration in managing thiols is the role of yeast. It is only by the activity of yeast that the flavourless precursors are converted into aromatic thiols. Only a few yeasts can do this as it requires the presence of the correct nucleotides on the IRC7 gene which is responsible for β-lyase activity that catalyses the conversion of these sulphur precursors into volatile thiols. This is most often associated with non-Saccharomyces strains, which have poor fermentation characteristics.

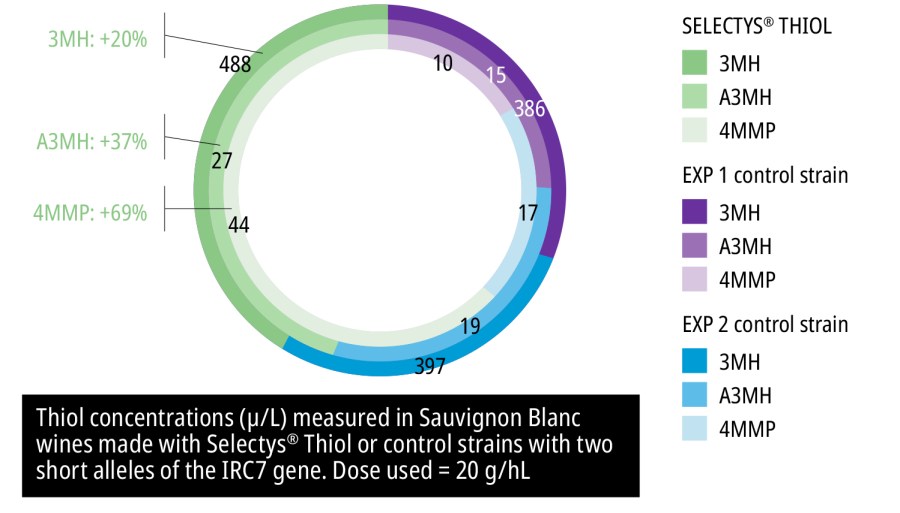

Selectys® Thiol however, was selected due to the presence of two long alleles of this gene and significantly increases levels of thiols. Particularly with regard to 3-Mercapto-1-hexanol (3HN, passionfruit, pineapple, grapefruit) and 3-Mercaptohexyl acetate (A3MH, exotic fruit, guava).

Last, but not least, the role of copper is far too often ignored. Many yeast strains are copper intolerant and fermentation will be compromised by even small levels in the juice. Copper will also bind to the -SH group of thiols, lowering the aromatic intensity.

Fortunately, it can be removed from must with the addition of Diwine® Thiol, a fining product based on PVP/PVI that targets and eliminates the residual copper, thus protecting and ensuring the longevity of aromas.

In conclusion, the winemaker now has many tools available to maximise thiol content:

- Protection of pre-cursors from oxidation

- Extraction from skins by enzyme

- Conversion of aromatic precursors to volatile thiols by yeast

- Removal of copper to prevent binding

The impact of different fining products on the concentration of polyphenols in white and rosé wines. Absorbance monitored by measuring OD at 280nm. Doses used: Oenovegan® EPL (6.5 g/hL), PVPP (20 g/hL), Gelatine (5 cL/hL)

For more information on these products and others from Oenofrance®: david@bevtech.co.uk