The UK’s leading supplier of winemaking equipment, Core Equipment puts building relationships at the heart of everything it does, both when dealing with its growing customer base and with its impressive list of suppliers.

“We believe in working closely with our customers to make sure we support them through the whole process, and we build strong relationships with suppliers because that means we can rely on their commitment and support,” explained incoming managing director Daniel Tomlin.

When it comes to customers, Core Equipment’s support extends to providing in-depth commercial analysis on the costs and benefits of new installations, helping the grower or winemaker to understand the likely return on investment and supporting their decision making.

“Investing in a new winery can involve significant start-up capital,” Daniel went on. “We like to spend time with the customer, listen to their needs, evaluate their options, provide a consultative sales approach and help them create a viable plan that clearly sets out their budget for the project. Essentially, we help them with their business plan before supplying the equipment that will turn that project into a reality.”

Established in 2011 by founder Jonathan Chaplin, Core Equipment has grown rapidly over the years and is now one of the longest standing and most trusted winery equipment suppliers and service providers in the UK.

While careful not to make any claim to be the biggest, Daniel pointed out that supplying some 200-plus tanks and averaging ten new press sales annually, as well as multiple grape reception solutions, fermentation control systems, disgorging and bottling lines, as well as ancillary equipment such as pumps and filtration systems would certainly make Core Equipment a leading supplier to the industry.

Core Equipment, which focuses on full winery ‘projects’ as well as supplying a full range of individual pieces of equipment, has built eight wineries “from the ground up” in just two years and, in Daniel’s words, “has a foothold in pretty much every UK winery due to our longstanding presence in the UK wine market.”

It’s an impressive record and reflects a strong focus on delivering exactly what the customer wants and working with some of the best suppliers of quality winemaking equipment across Europe, something that has inspired a number of new relationships in past months.

“We have always worked with the best manufacturers. Our reputation stems from this, and we are constantly looking for innovation, new suppliers to work with and quality wine making equipment to ensure that we are market leading in the solutions we offer to our customers,” went on Daniel. “Working alongside globally renowned suppliers ensures we stay ahead of the curve and maintain our position as the ‘go to’ provider for UK winemakers.”

New suppliers join a carefully chosen stable of world-leading partners which has helped Core Equipment make such an impressive mark on winemaking in the past 15 years, including BUCHER Vaslin, Borelli Group, G A Kiesel and renowned stainless steel tank manufacturer Letina.

“Our ambition is to work with the best supplier in each area,” said Daniel. “We have worked hard to find the quality equipment that will allow us to give our customers the best possible solution and allow them to get on with the job of making wine without worrying about the reliability or suitability of their equipment.

The choice of Kiesel pumps is a case in point. “As someone once said to me: ‘Would you rather buy one pump which lasts for ten years or one pump every year for ten years’,” commented Michael Mason, Core Equipment’s management accountant and the man who offers his expertise around the commercial aspects of projects, including cash flow management, foreign exchange handling and invoicing.

“Deep diving into the commercial elements of any winery project not only facilitates the customer in their decision-making process but also helps us tailor project-specific solutions to make the journey with Core Equipment as easy as possible,” Michael commented.

Jonathan Chaplin is still very much involved with the ongoing development of Core Equipment but has now handed day-to-day control of the company to Daniel, Michael and a strong central team of committed and customer-focused professionals, all of whom contribute to the ongoing success story.

Daniel, previously the company’s sales manager, has been with Core for over seven years and joined from a strong, commercially focused career with a number of corporate businesses, operating in the oil and gas, facilities management and tourism industries.

“That background is very useful when it comes to tendering for projects, looking after customers and managing suppliers,” he said. “I aim to create a professional, commercial relationship but with a personal touch.”

Dealing with suppliers is an area where Daniel invests a lot of time and effort. “Without suppliers we have nothing, so it is important to focus on that relationship,” he explained. Members of the Core Equipment team regularly visit exhibitions across Europe, support training days and seminars and “work hard at establishing ourselves as an active part of the manufacturing and supplier community,” he said.

“The UK is a comparatively small market for many of these suppliers and we need to ensure that we are being provided with the focused support we need to best serve our customers,” he went on. “We need to know that they will provide what we want, when we want it, especially on the occasions when we have a customer request away from the norm. That’s only possible because we take time and effort to build a relationship with each and every one of them, and I’m proud to say that’s exactly what we do.”

New suppliers, strengthened relationships and a renewed focus on delivering the best possible service to the customer has seen Core Equipment, which can provide everything a winery needs, continue to grow its turnover, reputation and market share.

An in-house project management and service delivery team means Core Equipment can deliver entire turnkey winery projects, while the customer focus ethos provides newcomers to the industry, in particular, with as much support as they need or want.

“Our aim is always to add value between the manufacturer and the end user while taking the stress away from the customer,” said Daniel. “We can manage the project from grape to glass, turning an empty barn or purpose-built building into a winery. We produce detailed CAD drawings and 3D models of the equipment we are providing, which really brings to life the project for the customer. Supported by detailed project plans, method statements and scope of works documents, we add value at every step of the journey.”

Core Equipment continues to grow and is always looking for new recruits to join the team working with customers nationwide. The good news for winemakers in the South East is that Core Equipment is planning a sales and service office in Sussex for 2025.

“It is important to be ‘part of the family’,” said Daniel. “It will allow us to be more reactive as well as proactive and allow us to further develop our service offering.”

Servicing is an important part of the Core Equipment offer and is in the hands of service manager Colin Sene, the longest-standing member of staff and responsible for on-site installations. “Colin has a wealth of knowledge and years of experience,” commented Daniel.

Colin’s three-strong team now includes service engineer Duncan Lewis, described by Daniel as “an excellent engineer and brilliant with customers”. As well as installations, Colin’s team provides a full servicing package and can maintain and repair a broad range of winemaking equipment, whether or not it was supplied by Core Equipment.

The company, which is looking to take on at least one more engineer, offers service contracts as well as responding in the event of an equipment breakdown. Colin’s team will be based in due course in the new Sussex satellite office along with business manager Jeaffreson Patterson.

Jeaffreson, described by Daniel as “fully immersed”, is a Plumpton wine-making graduate who has many years of operational winery experience and has worked in France, Australia and the USA. “He has strong relationships with winemakers, vineyard managers and owners across the industry,” said Daniel.

Given the complexity of importing equipment and, in some cases, building a new winery from scratch, purchasing and supply chain manager Nicola Peters plays a vital part in the efficient running of Core Equipment, relying on her 15 years’ experience in the beverage industry.

Equally important is Kirsty Goepel, the company’s operations manager and who is “incredibly detail focused” in the words of Daniel. “Kirsty is a highly reliable and supportive member of the team with a real eye for detail,” he commented.

With Core Equipment continuing to provide a high level of project delivery to the UK wine industry, Daniel summed up the company’s approach to its customers. “If you are investing a significant amount of money on a new winery or equipment upgrade, you are entitled to expect the best possible service and support, something we pride ourselves on delivering and which sets us apart from our competitors,” he concluded.

Core suppliers

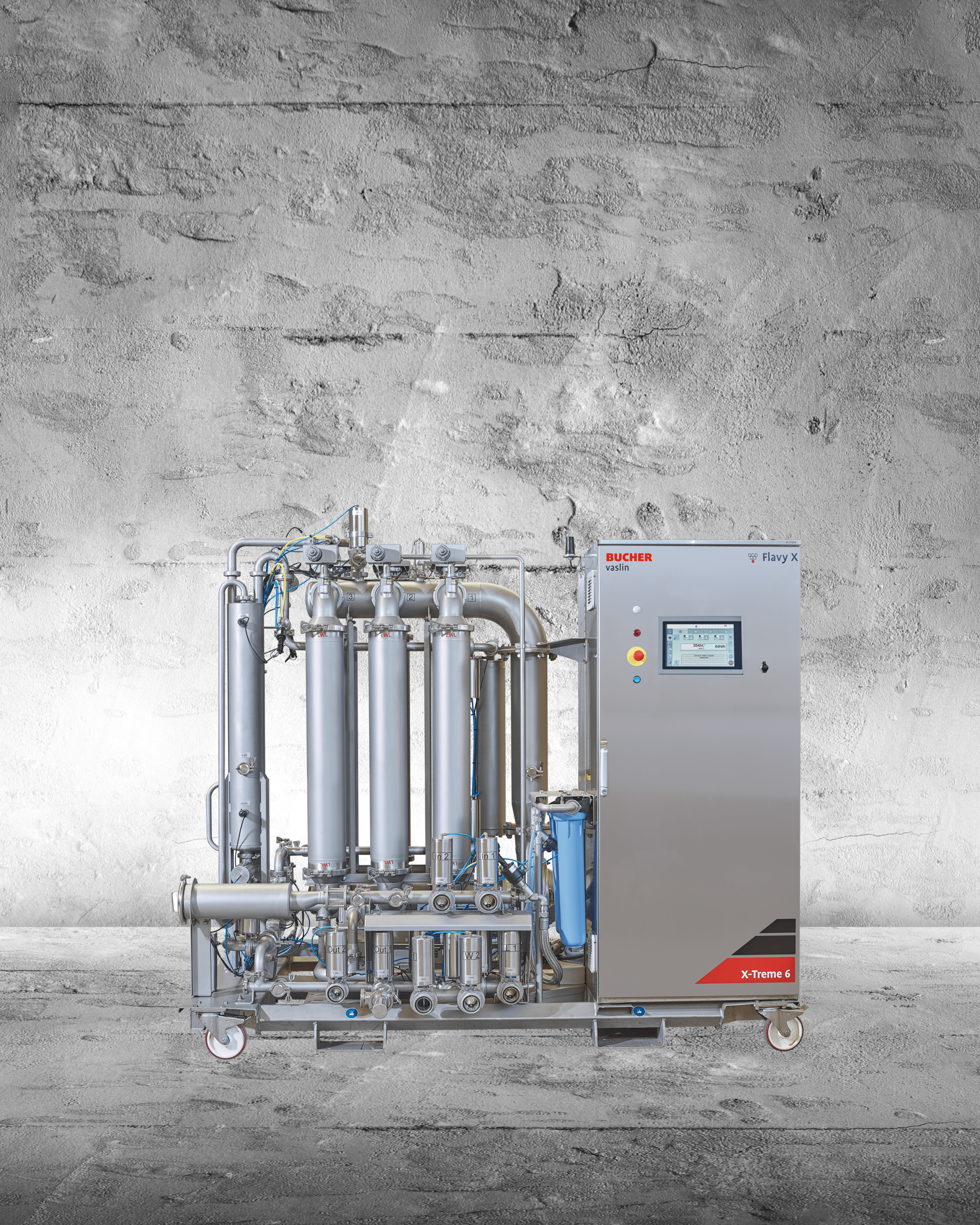

Core Equipment is the sole distributor in the UK for the BUCHER Vaslin range of grape reception, sorting, pressing and filtration equipment, together with crossflow and pump technologies. “It’s the Rolls Royce in its field,” commented Daniel.

Letina’s unbeatable manufacturing quality, allied to the wide range of capacities on offer, has seen the tank supplier become one of Europe’s success stories in the global winery equipment market. Core Equipment supplies between 150 and 200 stainless steel Letina tanks a year, in sizes ranging from 500 litres to 100,000 litres.

Sparkling Equipment provide a full range of winery equipment, covering every stage of production – from tirage to Isobaric filling, riddling to disgorging, corking, and wire hooding. Solutions cater to wineries of all sizes, offering both manual and fully automated systems to suit different production needs. Whether you’re a small producer handling a few hundred bottles per hour or a large-scale operation processing thousands, their equipment ensures precision, efficiency, and consistency at every step. With advanced technology and customisable options, Core Equipment can help you achieve the perfect sparkle in every bottle.

Thermoregulation experts LiquoSystems are a German supplier that specialises in temperature control systems for storage and fermentation tanks and employs the latest technology supported by more than 25 years’ experience in the industry.

Dogliotti offers a wide range of bottle conveyancing systems for both complex and simple bottling lines. The range includes buffer and accumulation tables, single and multi-track conveyors, standard and frictionless corners, side and parallel transfers and rotary pack-on and pack-off tables, as well as bespoke packing systems.

Capturing and interrogating data is increasingly important when creating quality wines, which is where French manufacturer Onafis’ live data capture systems can help. Capturing information such as temperature, density and Brix, Onafis promises “Solutions for monitoring the grape harvest, fermentation and maturation processes.”

German pump manufacturer Kiesel is renowned the world over for its quality range of impeller pumps, eccentric screw pumps, centrifugal pumps, mash pumps and rotary lobe pumps as well as for supplying the company’s RG range of agitators. Robust and reflecting German build quality, they well deserve their reputation.

Based just outside Canelli in the Asti region of Italy, Borelli benefits from being close to the centre of the Italian bottling and packaging industry, which allows it to benefit from specialist supply chains and technical expertise. Its impressive range of bottling machines reflects that quality input.

GG Technik is another German supplier, in this case of sterilisation equipment, including steam generators, bottle steamers, pasteurisers and barrel and pump cleaning technology.

Pozvek is a new, Croatian-based Core Equipment supplier that uses top quality Slavonian oak to create barrels used for maturing wines. The wood is cured for two months outdoors before being used for 150, 225, 300 or 500 litre barrels.