A label is so much more than a decorated piece of paper – it makes your wine stand out on a crowded shelf, it represents your brand, your story, your values and identity and it speaks to your target market. A label must attract customers to drive sales, carry product and legal information – and withstand the rigours of the ice bucket and the chiller cabinet. Vineyard speaks to Royston Labels to find out how their gold star service, skills, technology and craftmanship ignites your label and brings your brand to life.

The label experts

Based in Royston near Cambridge, Royston Labels is a privately owned company, established in 1984, with a state-of-the-art production facility, a team of 80 full-time staff and a dedicated drinks label division. At the centre of operations is Managing Director Paul Clayton, and the engine at the heart of Royston is a technical team focused on developing new products and market innovations to enhance their clients’ packaging and brands. “We produce over 400 million labels per year and our award-winning team of experts can be relied upon to deliver fantastic results,” commented Paul.

Royston has recently consolidated four production sites to a purpose renovated ultra-modern 65,000 sq ft facility – it’s spacious, immaculate, and high tech making it reminiscent of the ‘starship enterprise’. “The move and additional capacity have given the business a clear direction and growth plan for years to come,” said Paul. “We combine our knowledge of traditional print technologies with the latest in digital innovations, to ensure that our clients always receive the most cost-effective, high quality packaging solutions available,” he added.

Proud to offer a gold star service

Royston offers the full range of label production, both conventional and digital, as a tailor-made service for clients. “From the initial brief to printing the final label we pride ourselves on our exceptional quality in production and service, while supporting our client through their packaging journey. We have time for our clients and protect them from costly pitfalls – which can happen with the wrong supplier,” said Paul.

“We have our own studio where we can carry out pre-press services, including artwork updates and colour retouching. We regularly work with a large variety of drinks packaging designers in the UK, but as they don’t always have production experience, we help with any technical challenges and add value by making sure artwork is printable.

“We have extensive printing facilities including equipment for conventional combination printing and embellishment techniques. In the last decade, we have invested heavily in our digital printing capabilities, giving ourselves and our clients, greater flexibility when it comes to design, lead times and pricing.

“Our team are accustomed to using our equipment to produce complex, decorative labels for a variety of industry sectors, and because we understand the importance of innovation, we have an investment plan in place that allows us to update our technology as frequently as possible,” added Paul.

Royston Labels aim to provide a quality service at a competitive price. “People are often surprised by how affordable our service is. They are always very pleased when we make the process so much easier for them and get the results they want – on time.

“The devil is in the detail – we provide the skills and craftmanship, the care and attention, needed to make a great label, something that can be lost in a digital world. We care as much about the brand as our clients do, which builds the relationship and trust, and sustainability alongside responsible sourcing is thread through everything we do.

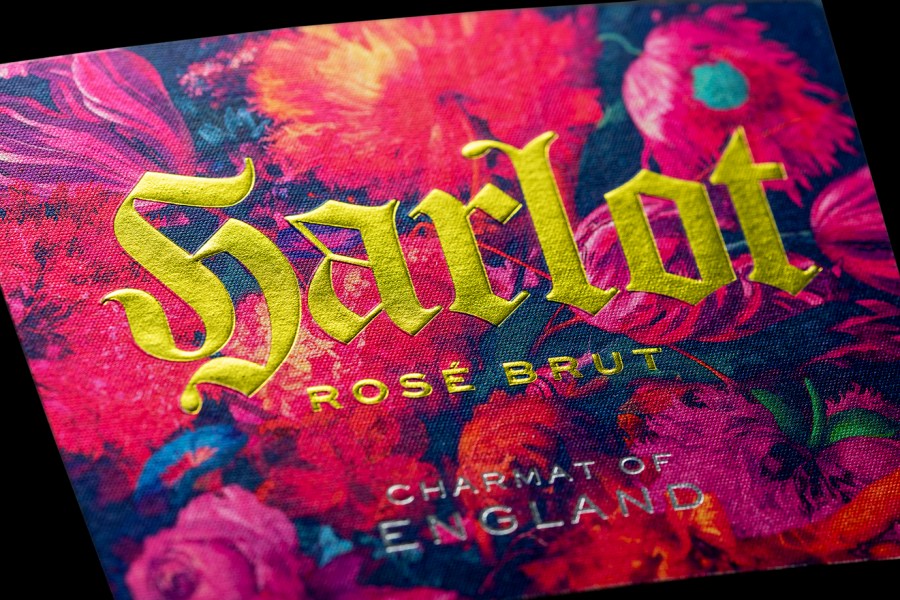

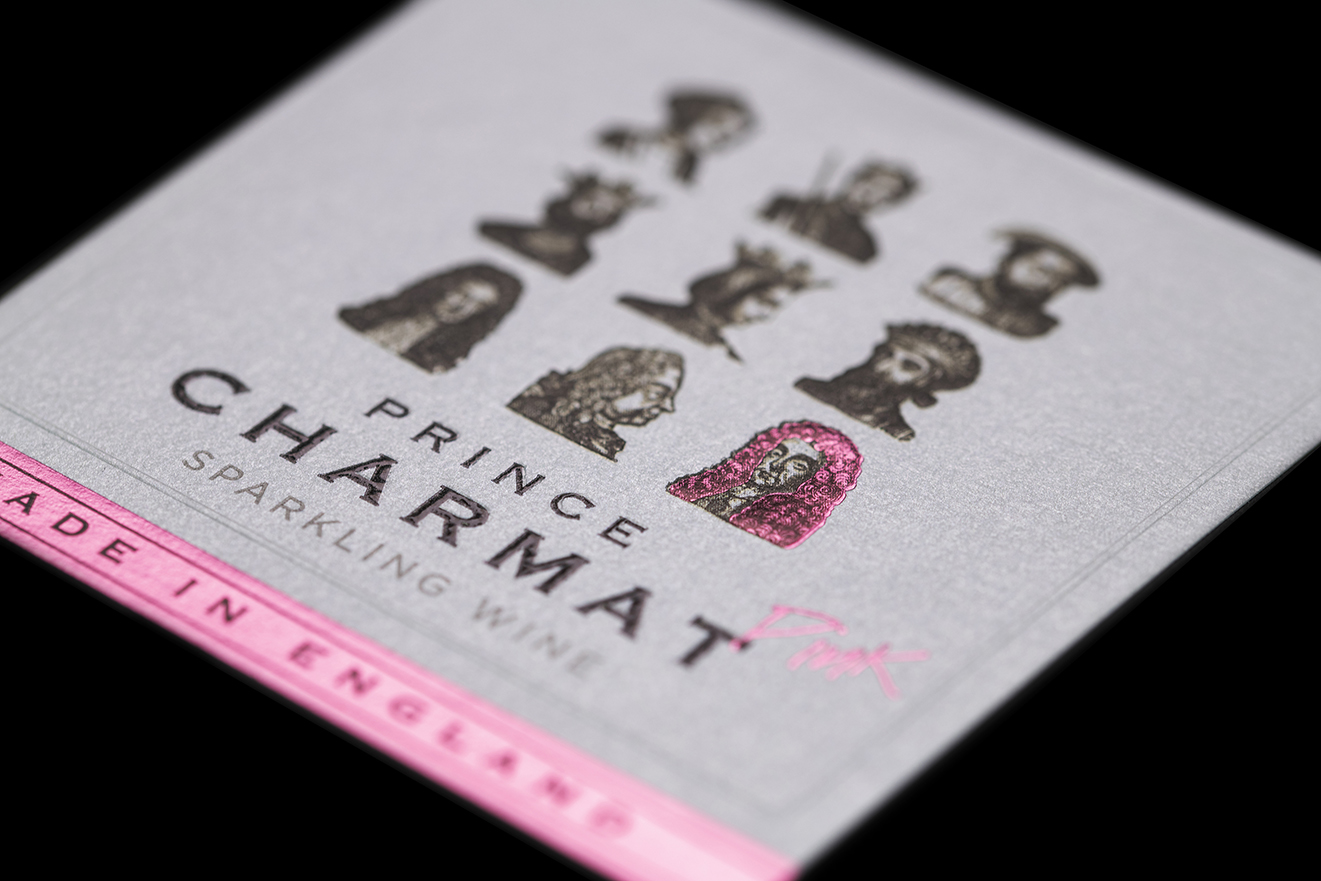

“We love to activate our client’s brand vision and celebrate the stunning end results with them. We are blown away by how wonderful the testimonials are we regularly receive, and by our customer loyalty. We work with a large cross section of UK Wine producers including major Vineyards like Hattingley, Hambledon and Denbies.”

“Royston have been the best label company we have used at Hattingley. They are large enough to have the very latest equipment with some fantastic embellishments available. However, they are small enough to give the utmost care and attention to us as a client. They are the professionals at this, and they deliver the knowledge and understanding that we need as a winery. I cannot recommend them highly enough.”

Gareth Maxwell, Hattingley Valley

An expert team

The dedicated Drinks Division team enables Royston Labels to provide the best in expertise, service, quality, and value to both new and existing clients.

Paul Clayton has been with the business for over 30 years. His print background and manufacturing experience, a creative flair and an eye for detail have stood him in a good position to develop the business and the team. “I focus on always taking an exceptional quality approach to everything the business does and produces. This combined with our industry experience and technical expertise has allowed us to develop very strong, long lasting customer relationships that are built on trust, honesty and reliability and have driven good growth for us,” commented Paul.

Glyn Scriven is Head of Sales in the Drinks Division. Glyn has been in the paper and packaging market for many years, including working with and supplying many UK wine producers. “It is something that I have been very interested in and actively supporting. Working for wine label material manufacturer Avery Dennison, I have experience in label printing, along with closure manufacturing – foils, corks, and wire hoods, which has stood me in a strong position to offer sound advice and guidance to UK wine producers. I am passionate about supporting our UK industry and seeing it succeed in all markets here and abroad,” commented Glyn.

Josh Clayton is Account Manager for the Drinks Division and works with Glyn Scriven to support clients for their label production. “Josh started with Royston after graduating with a first-class honours degree in Business Management. His main focus is the smooth processing of orders, ensuring the customer is kept informed at all stages of the project – and not forgetting his sharp eye for detail,” commented Glyn.

John Bousted has been part of the Royston team for over 20 years, following an apprenticeship and studying with the Watford College of Print. His role is vital to the drinks team as he manages the inhouse studio who take a brand’s initial designs and ensure technically that the artwork will support production in making the very best quality of label.

“Wine producers use the label to create a point of difference on the shelf, they look to push what can be achieved through multiple embellishments, techniques and finishing and John provides the guidance Royston clients need to best achieve their vision,” explained Glyn.

“It is only through a highly trained team utilising our skills, craftmanship and experience that make some of the packaging demands possible, everything has to come together to deliver the best result.”

“It is only through a highly trained team utilising our skills, craftmanship and experience that make some of the packaging demands possible, everything has to come together to deliver the best result.”

Paul Clayton.

The technical complexities

Royston Label’s experience and expertise prevent the pitfalls and hurdles often encountered in label production. “The real value we add for the client is the ability to support them technically, evaluating the design and ensuring that the desired outcome for the label is achievable.

Typical technical challenges and considerations:

υ Selecting the correct specification of material and adhesive to ensure that all elements of the design are delivered – and the label stands up to the ice bucket

- Choosing the appropriate printing process and embellishment technique to satisfy the design and the material being used

- Ensuring correct sizing, shape, and presentation of labels for the best, and most efficient, application – especially if the label is to be applied to a tapered area

- Neck Labels add additional complexity and certain requirements, such as the correct shape for the taper of the neck of the bottle – so Royston offer a templating service for customers. The choice of material and adhesive are critical, but also embellishments and varnishes need to be placed correctly on the label surface, so that adhesion to the bottle and the foil are not hampered.

“The main advances in label design we have seen are focussed on embellishments and the potential of using digital devices to add foil and raised varnishes. Label embellishment, if done well, can really enhance the label design, and there are many options – each with their own challenges. Royston have ensured that no matter what is designed or expected from the packaging we have the technology available to provide the very best results,” explained Paul.

Embellishment techniques available at Royston

- Hot foiling: traditional and popular technique for the eye-catching, premium finish it brings to packaging

- Embossing and debossing brings added detail and texture to your label

- Flat and fluted foil blocking

- Multi-level embossing

- 3D sculptured embossing dies

- Textured foiling dies

- Raised, tactile and spot varnish which provides a layer of protection to the material, while boosting its visual appeal.

- Cold foiling: efficient and affordable foiling solution for coated surfaces.

Sustainable and responsible

Royston Label’s sustainability strategy is based around reduce, reuse and recycle. “We ensure that our team have extensive knowledge and experience of the complete supply chain and recycling process, and can advise customers on the most practical solutions,” explained Paul.

“More recently we have been able to widen our range of recycled materials, some of these really do look the part and provide brand owners with a compelling story. An example would be rCrush Grape, rCrush Citrus, rCrush Barley and rNatural Blanc, some of these have the by-product from the fruits processing incorporated in the paper but all have a high percentage of recycled content. We also have a paper that is made from 95% sugar cane waste with hemp and linen – samples of all of these papers printed are available from the sales team.

“We are also committed to being a zero to landfill site. Working with our recycling partners, all production waste is recycled including the waste matrix, glassine and PET liners, inks and rags,” explained Paul. “During 2020 our achievements include: 83 trees saved, 55.77 tonnes of waste recycled from waste matrix as well as 12 tonnes of recycled glassine liner,” he added.

“Royston Labels is able to offer the widest selection of FSC certified papers; to ensure complete traceability and a focus on these values the company decided that accreditation was vitally important and was awarded FSC Certification earlier this year. The production facility also boasts accreditation to ISO9001, BRC AA and PS9000. Royston really do have a responsible sourcing process and where possible we source from the UK and Europe,” explained Glyn.

“For labels, recycled content can be included in the facestock and in the liners such as those using rPET, which is a strong and lightweight plastic that is recyclable. This type of carrier is much thinner bringing benefits such as strength during the application process and more labels per reel improving production efficiency.

Another area not to be forgotten is the adhesive and wherever possible these are water based avoiding the use of solvents,” Glyn added.

Sharing successes

“Royston Labels are proud to support and help develop the UK wine industry and our continued sponsorship of WineGB, and the Vineyard & Winery show in November, is testimony to this. We have great winemakers and producers in the UK, and we will continue to support anyway we can to see this become the success we all want.

“Before Glyn joined, we already had several UK vineyard customers, but since Glyn’s arrival we have had great focus which has brought on many new producers. We are able to offer, the label qualities and design features that the industry is looking for and have produced some really great results for our clients,” smiled Paul. “We are now supplying many vineyards with their labels, with new ones contacting us weekly to help them with their branding and labelling,” Paul added.

Favourite wine from England or Wales?

“I couldn’t possibly name just one – suffice to say I do have three or four favourites!” Glyn exclaimed.