It is well known that mechanical weeding is just as effective as herbicide when it comes to vine health and increasing yield.

A three-year integrated weed management trial, IWMPRAISE, which was carried out on Chardonnay at NIAB EMR’s Kent-based research vineyard, effectively proved that all the mechanical weeding methods which were trialled positively impacted the health of the vine as well as the yield.

Data also showed an insignificantly small difference between the mechanical and chemical treatments in vine vigour, nutritional status, inflorescence counts, and yield. Looking at weed abundance and coverage too, mechanical weeding successfully resulted in an overall decline in total weed coverage over the growing seasons in the trial.

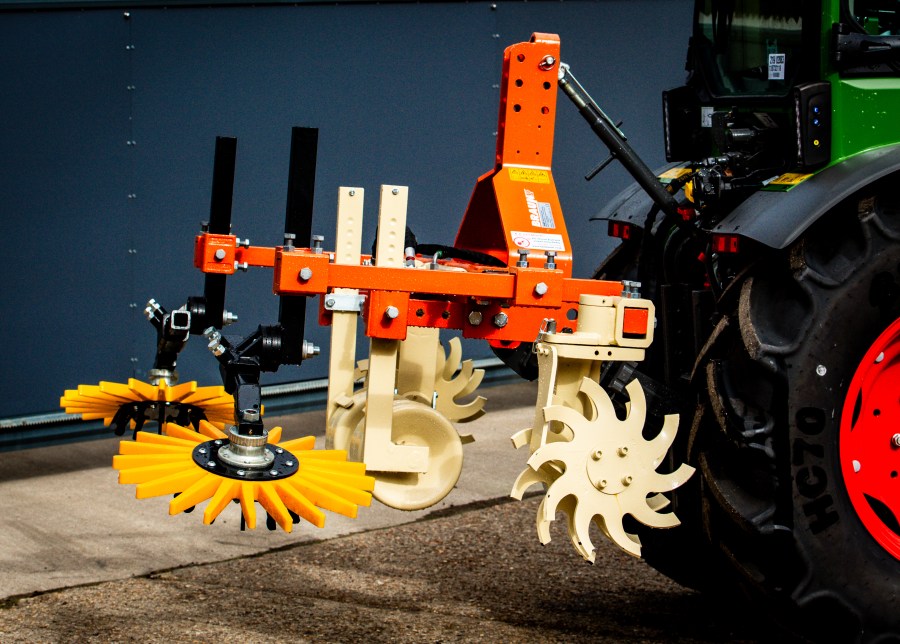

One of the mechanical weeding tools used in the trial was a rotary star tiller and finger weeder. Instead of breaking the soil, rotary tiller weeders effectively move through it, making it more friable, light, and fluffy. The horizontal finger weeder then distributes and levels the soil. This creates an inhospitable environment for weeds looking to establish themselves.

The Braun Rollhacke rotary star tiller has been identified as the best on the market and is the clear weapon of choice for vineyard managers across the UK, having proven to be adaptable to different soil types.

With 60ha of vines on Wealden Clay with Tunbridge Wells sand in Appledore, Kent, and 30ha on flinty, clay loam over chalk in Halnaker, Sussex, Gusbourne Estate has several tractors equipped with double-sided Braun Rollhackes.

Having seen how popular they were in Germany, Gusbourne’s chief vineyard manager Jon Pollard started using the Rollhackes as soon as NP Seymour started importing them.

“Initially, we were going to do a trial, but the Rollhacke did so well in the first plot that we decided to use it across all sites, and we have had above-average yields in all the years since,” said Jon.

For those worried that mechanical weed control will increase compaction or fuel consumption, Jon said that the Braun equipment, which is put through the vineyard around 12 times per year, is mostly combined with mowing operations.

“If we didn’t have the Rollhackes we would still be mowing the alleyways eight times per year, and we would be doing four passes of herbicide, so our overall tractor movements would be no different,” said Jon. “When it comes to the soil structure, too, you are only turning the top four or five inches, not going down where the vine roots are and so I feel there are no issues there with soil biology.”

For those who do not want to impact the soil in any way, Braun has also developed the Vine Trunk Cleaner. While initially brought to market to help growers with the backbreaking task of bud rubbing, this strimmer-like machine effectively controls unwanted vegetation growth and weeds between the vines.

Growers can choose to mount the units on NP Seymour’s bespoke front-mounted tool carrier, or alternatively, they can be attached to the Braun mid-mounted vertical hydraulic lift arms.

For those looking for optimal efficiency and wanting to combine mechanical weeding and mowing tasks, the Braun Vine Trunk Cleaners can also be easily fitted onto a variable-width Braun Alpha mower.

The Braun Alpha variable width can be hydraulically adjusted depending on the model as standard. Growers can also opt for the upgraded Sensotronic, which uses a sensor to detect the rows and continuously adjust its working width while driving.