Unreliable yield forecasts cost money, waste resources and depress profitably. Poor forecasts are one of the largest causes of tension, stress and conflict between vineyard managers and winemakers. Vineyard finds out why it’s important to improve accuracy and which forecasting methods work.

Even as the season starts the winemakers will be asking the vineyard manager how much fruit there will be at harvest. If the vineyard manager under forecasts and more fruit comes in than expected, there may not be enough capacity in the winery and picking may need to be delayed – with quality implications. Staff and storage space could also be in short supply. But if less fruit comes in than expected capital investment in tanks, other equipment or oak, could be wasted expenditure. Both scenarios also have an implication on consistency of supply to the market – a challenge for the sales and marketing team.

Improving accuracy

Dr Greg Dunn, Head of Wine at Plumpton College, is a leading expert on yield forecasting, as this was his area of research when Associate Professor at the University of Melbourne, Australia. “Vineyard managers across Australia were asking how to get forecasts right due to the cost implications for both over and under forecasting – and these economic and quality implications can be substantial. Ideally winemakers want an accuracy of + or – 5% from the vineyard managers forecast, but the data in the Australian wine industry at the time showed that forecasting accuracy was more like + or – 30%. Although I do not have enough data for the UK to determine, on average, how accurate yield forecasting is, I suspect it would not be dissimilar. If any grower would like resources to improve their yield forecasts, then contact me at Plumpton College.

“The winery needs to organise harvest, arrange labour, allocate tank space, plan oak requirements, schedule fruit receival, and purchase winery supplies. From a broader perspective, production and stock management need to be linked to marketing efforts. However, crop yields vary substantially across the vineyards and from season-to-season, making forecasting a challenging task for the vineyard manager,” Greg commented.

“Yotes Court Vineyard is a fairly new vineyard and 2018 was our first harvest so we had no historical bunch weights to use in the calculations, but the last two seasons have been very accurate, 100% accurate in 2019,” commented Tony Purdie, Vineyard Manager.

“Our forecasting varies from season to season and block to block, but overall its usually pretty good, usually within 5% – but block variability always makes it difficult to get every block correct,” explained Cameron Roucher, Vineyard Manager at Rathfinny Estate.

Components of yield

“The components of yield, that is the weight of fruit per vine, is a function of the number of bunches per vine, the number of berries per bunch and berry weight,” explained Dr Greg Dunn. “Our research in Australia showed that bunches per vine closely tracks yield per vine, more so than berries per bunch. In fact bunches per vine accounted for around 60% of season-to-season variation while berries per bunch accounted for 30%, and weight per berry only 10%. So, forecasting starts with bunches per vine and then it can be fine-tuned with berries per bunch. My advice is that if you do one thing – take time to make sure that your inflorescences counts in spring are accurate. Then after fruit set, you can reassess to fine tune your forecast.”

Greg suggests initially sampling 30 vines per block. “To avoid bias these vines need to be randomly selected, using appropriate software. It’s OK to keep the same vines year on year as marker vines, as long as these vines are not managed any differently and you don’t sample fruit from them during the season. It’s important that all vines have the same chance of being samples. This includes weaker vines and even missing vines as these all contribute to overall yield. Finally, it’s important to collect data at the end of the season (at harvest) to find out where your forecast might have been out and to use this knowledge to improve your forecasting for the following season.

“Yield forecasting is not easy so it’s important to be rigorous and diligent when taking measurements. If it’s not done properly you are wasting your time,” Greg added.

Tony Purdie at Yotes Court Vineyard uses technology to help his forecasting, and reporting. “We use Vidacycle’s Sectormentor app on our phones to gather all the inputs and generate specific or general reports based on the detail required. We have 4 x 5 vine sampling bays which are data tagged and GPS located per block. These 20 vines are routinely observed and recorded throughout the growing season.”

“The first round is counting bud numbers left at pruning which gives us the fundamental information at the start of the season. We then do shoot and floret counts pre-flowering, when they are still easily found and if required this information can be used to determine a shoot thinning regime.

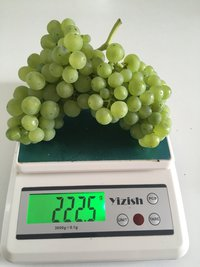

“The next task is during the lag phase (after the berries undergo a rapid cell division from flowering to post pea size), when we take bunch counts of the 20 vines. This is followed by a “destructive harvest” of one vine per bay in each of the four sample bays. The fruit is cut and counted off the vine carefully into a bucket. This is kept as a single vine sample so each bunch can be weighed, and each berry per bunch counted. The stem is then weighed and deducted from the initial bunch weight to give an accurate berry weight at lag phase. Then the maths, as a multiplication number needs to be determined. As a general rule the lag phase berry will double in weight through veraison to harvest, so we use a multiplying factor of two.

At pre-veraison, using the lag phase destructive harvest bunch and berry count numbers, we can now determine the final harvest weight by multiplying the average determined harvest bunch weight per vine by the number of cropping vines per block. All non-productive vines or missing vines need to be subtracted from the total block vine count,” explained Tony.

New technologies

There are potentially new technologies that will help with improving the accuracy of yield forecasting in the future. “We have started to use the Greenview AI product from Bitwise Agronomy this season. This sort of technology is the future of yield prediction (and more!). At present we have used it to do node and cane counts, and will be using throughout the season,” explained Cameron Roucher.

“Sectormentor has really streamlined the data gathering and reporting process of crop estimation and is evolving every year to help the grower fine tune the process. Spectral analyses of crop loading is still a work in progress but I am sure will be a tool in the future,” commented Tony.

Winery planning

Nick Lane, Winemaker at Defined, a contract winery based in Kent, finds that accurate yield forecasting is crucial for his planning. “We encourage our clients to do the best they can. Some things can be adjusted late, but some are more fixed. Determination of tank space and pressing capacity are investments that require a long lead time. Harvest labour and winery supplies can be fine-tuned much closer to the harvest. However, an overestimate may result in capital investment (tanks and presses for example) that might not have been necessary.

“To help vineyards we run quarterly viticulture sessions with a vineyard consultant and crop estimation and management is a popular topic. Closer to harvest we will go and visit some vineyards to cross check their estimations. Having another set of eyes is really useful for fine-tuning the harvest requirements.

“We find that the most effective and useful method is sometimes the simplest. Walking the vineyard, counting inflorescences and later weighing a certain number of bunches at certain stages. After that it is basic arithmetic. One aspect which is really important for yield estimation is historical values which can be a challenge for young vineyards,” commented Nick.

“Ask any winemaker – forecasting is very important – for the basics such as dry goods ordering or what block goes into what tank, through to scheduling of jobs and labour requirements,” added Cameron.

“A year when practically every berry sets and every bunch is picked is a dream scenario for a grower – and the accountant – but a nightmare for a winemaker if they are not properly informed of potential volumes,” explains Tony. Vintage logistics and volume requirements in the winery have to be determined fairly early for the winery to adapt to the expected harvest, but late last-minute crop estimations or unrealistic predictions can have very impactful ramifications in the winery.”